Wire

in needleAt the end of the Middle Ages, industrial textile activity spread throughout France. In Ariège, the towns of Foix and Laroque d’Olmes were the main producers of woollen cloth. The Pays d’Olmes then went into a period of slumber, with the Aude region developing this sector.

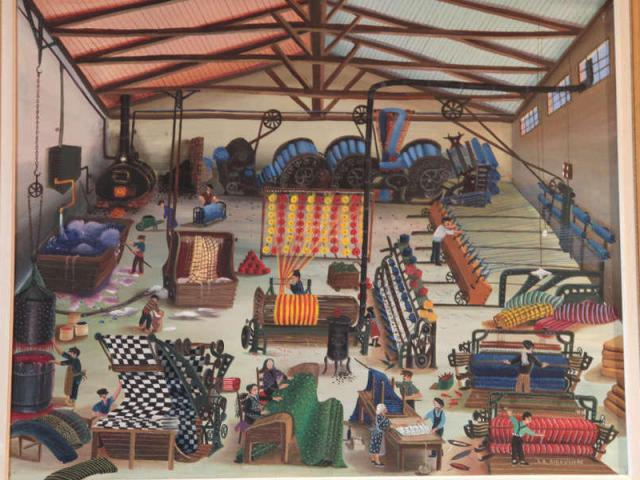

In the early 19th century, the beginnings of mechanization changed the situation and enabled textile manufacturers to set up in Laroque d’Olmes and Lavelanet. At this time, the textile industry was developing in Pays d’Olmes, but still remained in the shadow of the major centers of northern France.

At the beginning of the 20th century, local entrepreneurs specialized in the production of carded wool fabrics (untangled wool stripped of its impurities). This whole sector developed around Lavelanet, with wool spinning, fraying, weaving and finishing industries.

The presence of watercourses facilitated the installation of factories, and establishments flourished mainly along the Touyre from Montferrier to Laroque d’Olmes. Water was essential to the industry, providing the motive power for the machines and enabling wool washing, dyeing and some of the finishing processes.

Tapestry of Lice Textile Museum

Tapestry of Lice Textile Museum pr_82_sl_1_368_peinture_mady_giraudiere

pr_82_sl_1_368_peinture_mady_giraudiere P1130147

P1130147